Reasons Why You Should Consider the Utilization of Industrial Dispensing Arms in Production

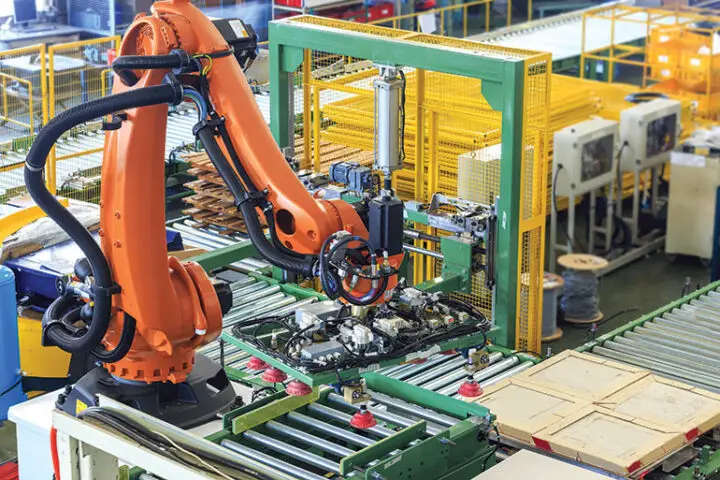

Dispensing robots are designed to handle small items such as tablets or batteries for counting, sorting, or packaging. They are also used to dispense fluids into packaging containers. The number of items or fluids to be dispensed can be set or adjusted as per requirements.

The employment of dispensing robots is more advantageous to human labor as these robots can work longer without tiring and more accurately than human hands. It’s also cheaper as they can perform a lot of tasks at a faster rate hence increasing output in the assembly line. Here are the top reasons why you should consider the use of these applying robots in the manufacturing process.

Increase Working Speed

Some tasks like counting small items or dispensing little amounts of liquids can be time-consuming and tedious for human beings. An arm for dispensing robots can be calibrated to perform such tasks more efficiently and at very high speeds, please visit www.evsint.com to learn more. This helps to increase the level of output in your firm and also minimize the time taken in production.

Cost-saving

Human labor comes with errors that could cause huge losses. Such mistakes include spillage or miscalculations. Automatic dispensation eliminates these errors hence cutting down on wastage or damage of products and raw materials.

Automation also cuts down on the number of workers required on a production line. Hence saving on the extra cost of salaries. They are also quick hence more is produced faster, increasing revenues. Robotic arms are highly precise. Hence every task is carried out without repetition saving on utility costs such as electricity.

Flexibility

Dispensing robots are often set to perform various tasks such as pouring and counting at desired intervals and measurements. They are highly accurate and not prone to errors like humans. They can even be set to provide unique shapes and various volumes. These can be extremely hard to realize while using human hands.

Precision and Accuracy

One of the main advantages of a robotic dispensing arm is that they are highly precise and accurate. Robots work exactly according to how they have been programmed without deviation hence their accuracy and precision. This translates to improved quality of the products produced by the company. There is also a huge reduction in losses incurred during the processing as there are fewer or no wasted defective products or raw materials.

Better Floor Space Utilization

Introducing robots into your line can help to decrease the footprint of a work area. This is made possible by the fact that almost all robots are fixed and work in a defined area without much movement. This extra floor area can be utilized in the firm for other production activities such as packaging and preparing products for storage or final deliveries.

Dependability

Robots are fast and highly efficient when it comes to performing their tasks. This is often the competitive advantage that robots bring to an industrial operation. They can perform multiple tasks perfectly and can be of great help when it comes to improving service delivery. The exact time they take to perform a certain task can be accurately defined. This helps firms to create plans guided by these precise predictions.

Improved Production Capacity

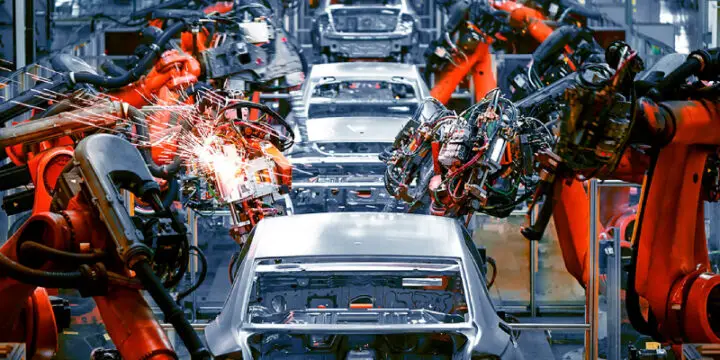

Robotic arms help firms increase their productivity owing to their nature. These are machines. They can work without calling in sick or taking breaks. They don’t sleep either and so they can be productive for far longer hours than humans. They can also work faster and accurately than any human worker. As a result, they will produce more in a given amount of time than humans can.

Improve Factory Working Conditions

Some types of work can be dangerous, unhygienic, difficult, or too dull for human workers. This type of role can be carried out effectively by robots. As a result, workers previously engaged in this work can be assigned to carry out other tasks under improved conditions. This is being highly advocated for by health experts and government agencies all over the world in an attempt to safeguard the wellbeing of factory workers.

Attract More Customers

Automation helps to provide the highest output with the least amount of spending. With a reduction in schedule and cost, your company will attract more clients. With these robots, one can increase the variety of products in the factory or improve the quality of the products already in production. This will help to retain and attract customers to the business thus raising the income revenues of the company.

Multiple Applications

Industrial machinery is usually integrated to automatically perform a variety of tasks such as counting, palletizing, cutting, sorting, packing, and dispensing. With automation, a single robot can carry out all these tasks efficiently. This goes a long way to reduce the cost of service and maintenance as only a single robot will be required.

Conclusion

In this age of technological advancements. The use of robotic arms is inevitable for most businesses who want to gain a competitive advantage or simply to just keep up with it. The advantages of robotic arms in a company are too many to ignore. And this being the current trend in production it’s a worthwhile venture.