Haul with Confidence: The Top Peterbilt Truck Parts You Need to Know

Peterbilt Trucks are renowned for their durability, performance, and style in the trucking industry. However, even the most reliable trucks require maintenance and occasional parts replacement. This blog post delves into the essential Peterbilt truck parts you should be familiar with to ensure your vehicle remains in top condition. Whether you’re a seasoned trucker or a fleet manager, this guide offers valuable insights into the world of Peterbilt truck parts.

1. Engine Components

Introduction

The engine is the heart of your truck, and maintaining its components is crucial for optimal performance. Understanding the key parts of your truck’s engine can help you spot issues early and prevent costly repairs.

A. Filters (Oil, Air, Fuel)

Importance

Filters in a truck play a vital role in maintaining the engine’s health. Oil filters keep the engine oil clean, air filters ensure the intake air is free of contaminants, and fuel filters keep impurities out of the fuel system. Regularly checking and replacing these filters can significantly extend the life of your engine.

Maintenance Tips

To ensure peak performance, replace oil and fuel filters at manufacturer-recommended intervals. For air filters, monitor for clogging or damage, especially in dusty environments. Using high-quality filters designed for your specific Peterbilt model is crucial for optimal engine health. For a selection of high-quality filters and further guidance on choosing the right components for your model, visit https://www.mrhydraulic.com.

B. Turbochargers

Functionality

Turbochargers are vital for boosting engine power and efficiency. They work by compressing air into the engine, allowing more oxygen for combustion. This results in increased horsepower without significantly increasing engine size or fuel consumption.

Signs of Wear

Be aware of symptoms like reduced acceleration, increased fuel consumption, or unusual engine noises, as these might indicate a failing turbocharger. Regular inspections and prompt replacement of worn parts are key to maintaining the turbocharger’s performance.

2. Drivetrain Components

Introduction

The drivetrain is essential for transmitting power from your Peterbilt’s engine to its wheels. Understanding these components ensures smooth and efficient operation.

A. Transmission

Types and Maintenance

Different gearbox types—manual, automatic, and automated manual—are included with Peterbilt trucks. Every kind has different upkeep requirements. It is essential to do routine fluid checks and changes, leak detection tests, and strange noise inspections.

Common Issues

Be vigilant for signs like difficulty in shifting gears, unusual noises, or transmission fluid leaks. Addressing these issues promptly can prevent more significant problems and ensure a longer life for your transmission.

B. Differentials’

Role in Performance

Differentials are crucial for allowing your truck’s wheels to rotate at different speeds, particularly when turning. This part is essential for handling and stability, especially under heavy loads.

Maintenance and Repair

Regular inspections for leaks and unusual noises are vital. Differential fluid changes are also crucial for longevity. Using high-quality lubricants and addressing any issues immediately can save you from costly repairs.

3. Brake System

Introduction

A reliable brake system is non-negotiable for safety on the road. Knowing the key components of your Peterbilt’s brake system and their maintenance can be life-saving.

A. Disc and Drum Brakes

Differences and Maintenance

They may have disc brakes, drum brakes, or a combination. Disc brakes offer better heat dissipation, while drum brakes are more common in heavy-duty applications. Regular inspections for wear and tear, along with prompt replacement of brake pads or shoes, are essential.

Signs of Problems

Symptoms like longer stopping distances, squealing noises, or a pulsating brake pedal indicate issues with the brake system. Regular maintenance is crucial for the safety and performance of your truck.

B. ABS System

Importance

The Anti-lock Braking System (ABS) prevents wheel lockup during hard braking, maintaining steering control. This system is crucial for preventing accidents, especially in slippery conditions.

Maintenance Tips

Regular inspections for ABS sensor issues and checking brake fluid levels are essential. Any ABS warning lights on the dashboard should be addressed immediately by a professional to ensure the system functions correctly.

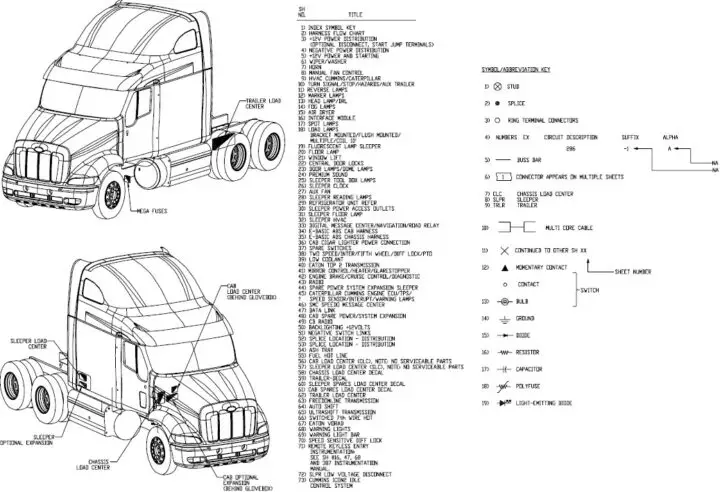

4. Electrical System

Introduction

The electrical system in your Peterbilt truck powers everything from the headlights to the onboard computer. Keeping this system in check is vital for the smooth operation of your truck.

A. Batteries and Alternators

Key Functions

The battery provides the initial power to start the engine, while the alternator continuously charges the battery and powers the electrical system when the engine is running. Ensuring these components are in good condition is crucial.

Maintenance and Replacement

Regular checks for corrosion on battery terminals and ensuring the alternator is charging correctly are important. Look out for dimming lights or issues with starting the engine, as these can be signs of failing batteries or alternators.

B. Wiring and Fuses

Importance of Wiring

Proper wiring is essential for the reliability of your truck’s electrical components. Faulty wiring can lead to malfunctions in lighting, sensors, and other electrical parts.

Fuse Maintenance

Fuses protect your truck’s electrical system from overloads. Regularly checking and replacing blown fuses can prevent more significant electrical issues. It’s important to use the correct fuse type and rating for your Peterbilt model.

5. Suspension System

A. Springs and Shock Absorbers

Role in Ride Quality

The springs, whether leaf or air springs, bear the weight of the truck and its cargo, while shock absorbers dampen the impact of road irregularities. This combination is essential for maintaining tire contact with the road and ensuring a smooth ride.

Maintenance Tips

Inspect springs regularly for signs of wear, cracks, or sagging. Shock absorbers should be checked for leaks and effectiveness. Replacing worn shocks and springs not only improves ride comfort but also enhances handling and safety.

B. Bushings and Joints

Importance in Suspension System

Bushings and joints in the suspension system reduce friction and wear between moving parts. They are essential for the smooth operation of the suspension components and contribute to the overall stability of the truck.

Signs of Wear and Maintenance

Worn bushings and joints can lead to handling issues, uneven tire wear, and increased vibration. Regular inspections for cracks, stiffness, or excessive play in these components are crucial. Prompt replacement of worn parts ensures the integrity and performance of the suspension system.

Conclusion

Understanding and maintaining these key Peterbilt truck parts can significantly impact your vehicle’s performance and longevity. Regular maintenance not only ensures your truck runs smoothly but also enhances safety on the road. Whether you’re a seasoned trucker or managing a fleet, keeping these components in check will help you haul with confidence.