Mastering Flame Treating: Tips for Maximizing Versatility in Applications

Flame treating, with its rich history and evolving techniques, stands as a cornerstone in numerous industries, from automotive to electronics. This unique approach to surface modification has revolutionized the way materials bond and interact. Its unparalleled significance is accentuated by its transformative ability to enhance intrinsic material properties, particularly adhesion. This enhancement is evident across a vast spectrum of applications, from simple bonding tasks to intricate manufacturing processes. In this comprehensive exploration, we’ll delve deep into the multifaceted world of flame treating, demystifying its intricacies, and showcasing the breadth of its versatility in modern industries.

Deep Dive into Understanding Flame Treating

When we talk about surface modification, flame treating emerges as a frontrunner. At its very essence, this technique harnesses the dual power of heat and oxidation to bring about transformative changes in material properties. When materials, be it plastics or metals, are exposed to meticulously controlled flames, a fascinating process unfolds. Their surface undergoes a rapid oxidation, making them exponentially more receptive to bonding with other materials. This oxidation-driven transformation not only amplifies adhesion capabilities but also ensures that the bond remains robust and enduring, especially in critical applications such as automotive painting, high-quality printing, and industrial bonding.

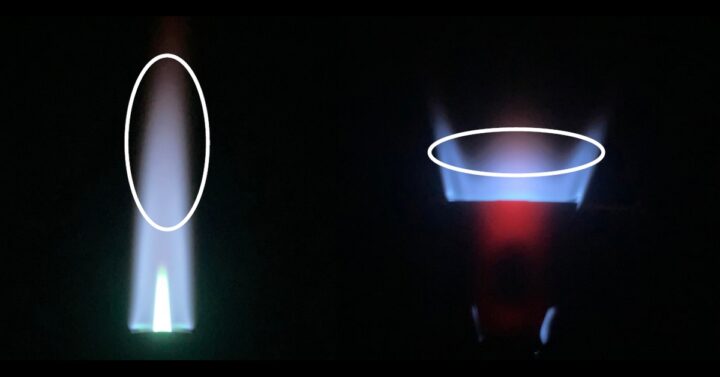

Foundational Principles of Flame Treating

Flame treating, like any scientific process, operates on a set of foundational principles. At the heart of these principles lies heat. As the primary agent, heat readies the surface, making it amenable to oxidation. Following closely is oxygen, introduced meticulously through the blaze. This oxygen interacts vigorously with the heated surface, instigating molecular changes that redefine the material’s bonding capabilities. Combustion, the third and equally vital pillar, plays a pivotal role in maintaining the flame’s desired temperature and intensity. When these elements synergize, they orchestrate a remarkable transformation of the material surface, optimizing it for superior adhesion and longevity.

Flame Treating in the Bakery Industry

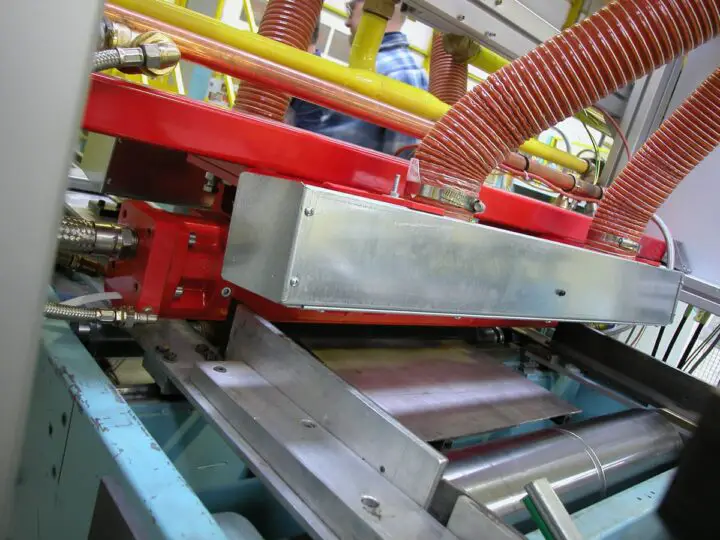

The bakery industry, known for its delectable creations and intricate processes, has found an unexpected ally in flame treating. When it comes to crafting certain baked goods, achieving the perfect texture and finish is paramount. Flame treating assists in caramelizing the surface of pastries, giving them a golden-brown hue and a delightful crunch. For baked goods that require specific toppings or glazes, flame treating such as Ribbon Burner ensures that these adhere seamlessly, enhancing both flavor and presentation. Additionally, certain packaging materials used in the bakery sector undergo flame treating to ensure labels and designs adhere perfectly, preserving freshness while showcasing the product inside. This technique, though unconventional in the world of baking, has proven invaluable, elevating both the aesthetics and taste of bakery products, and ensuring they stand out in a competitive market.

Identifying Materials for Flame Treating

The realm of flame treating is vast, but not all materials are equally suited for it. Plastics, with their unique molecular structure, often emerge as prime candidates. When flame-treated, their surfaces undergo a transformation, becoming incredibly bond-friendly and ensuring robust adhesion. Metals, too, when subjected to blaze treating, can manifest improved paint adhesion, making them ideal for industries that prioritize aesthetics. Textiles present another fascinating avenue. Undergoing transformations, especially during dyeing and printing processes, textiles treated with flame ensure that colors remain vibrant, prints are sharp, and the overall aesthetic appeal is magnified.

The Art of Enhancing Adhesion

Adhesion stands at the forefront of many industrial processes, and flame treating serves as its trusted ally. One of the standout benefits of this technique is its unparalleled ability to boost material adhesion. By meticulously removing surface contaminants and activating the material’s inherent surface properties, flame treating paves the way for superior bonding. Whether it’s paint on a car or glue on a circuit board, the enhanced bonding achieved post blaze treating not only elevates aesthetics but also ensures that the bond remains resilient, especially in applications that are continuously exposed to external wear and tear.

Automotive Industry and Flame Treating

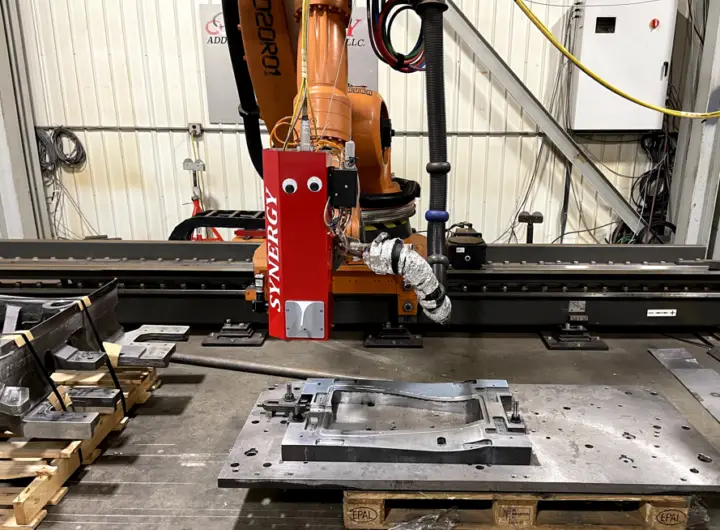

The automotive sector, a behemoth industry with a vast array of components and materials, leans heavily on flame treating. Interior components, predominantly made of plastics, undergo flame treating to ensure that upholsteries, fittings, and other elements bond seamlessly, enhancing both functionality and aesthetics. Furthermore, before the intricate process of painting car exteriors commences, blaze treating steps in. It ensures that the paint, whether matte or glossy, adheres uniformly across surfaces, resulting in a finish that’s not only flawless but also enduring, capable of withstanding external elements.

Packaging Industry’s Secret Weapon

In the dynamic world of packaging, where presentation often dictates consumer choices, flame treating emerges as a game-changer. This technique plays a pivotal role, especially when the goal is to improve ink adhesion on diverse packaging materials. Whether it’s the packaging for gourmet chocolates, high-end cosmetics, or everyday essentials, flame-treated surfaces guarantee that printed labels, designs, and critical information remain vibrant, legible, and resistant to smudging or fading, ensuring that the product inside is accurately represented.

Flame Treating Role in Textiles

The textile industry, with its perpetual focus on aesthetics, durability, and innovation, employs flame treating in a myriad of applications. This technique ensures that dyes bond harmoniously with fabrics, resulting in colors that are both vibrant and long-lasting. Furthermore, when it comes to printing, blaze treating ensures that prints, whether intricate patterns or bold designs, don’t fade or smudge. Additionally, in specialized coating processes, where fabrics are endowed with protective or aesthetic finishes, flame treating stands as an indispensable ally, ensuring results that are both visually appealing and functionally superior.

Medical Industry’s Reliance on Flame Treating

In the critical world of medical devices, where precision, durability, and reliability are non-negotiable, blaze treating plays a pivotal role. Especially during the assembly of medical devices, this technique ensures that diverse components, whether plastic housings or metal elements, bond securely and enduringly. The result? Medical devices that are not only functional but also designed to last, ensuring patient safety and operational efficiency.

Electronics and Flame Treating Synergy

In the rapidly evolving realm of electronics manufacturing, where precision is paramount, flame treating offers invaluable benefits. Circuit boards, often crafted from materials that demand enhanced adhesion, are subjected to blaze treating. This ensures that intricate components, from microchips to capacitors, bond securely to the board. The outcome? Electronic devices that are not only high-performing but also designed for longevity, meeting the demands of modern consumers.

Safety First in Flame Treating

While the benefits of flame treating are manifold, it’s imperative to prioritize safety. Engaging in this process necessitates the use of protective equipment, including heat-resistant gloves, face shields, and safety goggles. Given the potential for fumes and emissions, ensuring optimal ventilation is crucial. Moreover, considering the inherent fire risks associated with blaze treating, adhering to stringent fire safety procedures, including having extinguishers readily accessible, becomes non-negotiable.

Unlocking Flame Treating Full Potential

To truly harness and maximize the versatility of flame treating, strategic approaches are essential. This involves adjusting parameters based on the specific material in focus and the desired outcome, selecting the right equipment tailored for the job, and conducting regular tests to ensure optimal results. By meticulously fine-tuning these elements and staying updated with the latest advancements, one can master the art of blaze treating, unlocking its full potential and reaping its benefits across diverse applications.