4 Things You Probably Didn’t Know About Oil Purifiers – 2024 Guide

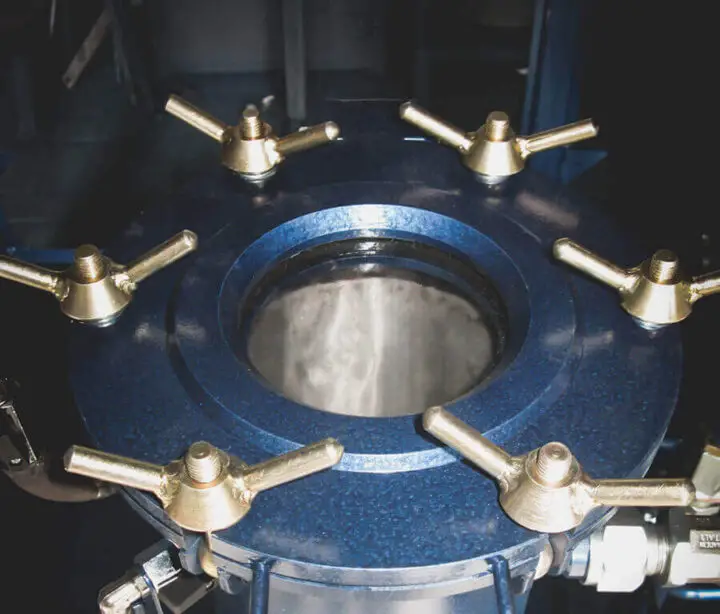

The main purpose of an oil purifier is to remove the particles from the oil and make it more suitable for different machines and engines. Different methods can be used for this process. However, the main advantage of an oil purifier is that it removes water and additional gases from the oil along with other substances and makes it cleaner. The key importance of these features is that they could provide machines with improved effectiveness and expanded lifespan.

There are many uses of this method in different industries, like manufacturers, where hydraulic machines require proper oil for functioning, vehicles, which are using various oils for proper operations of engine, ABS, and other systems. Besides that, we can find the implementation of hydraulic machines in many other processes, which makes this method essential today. If you are interested in buying this purifier, visit chinaoilpurifier.

However, before you invest in a business with oil purifiers, it is essential to learn more about the wide use of it, and the different functions that you can apply on oils to make them more suitable for diverse machinery. In this article, we are going to introduce you to some facts related to this device that most people are not aware of.

1. It Can Remove Water From Oil

While most people think that the main purpose is to remove particles and dirt from the oil, you should know that water can cause various issues as well. It depends on the type of machine, but in most cases, water can affect poor performance and the low power of the engine. Moreover, it can affect corrosion, reduced strength, and increased oxidation. Moreover, oil is much more resistant to high temperatures, which is also a very important feature in various machining processes. However, high amounts of water could negatively affect this resistance as well.

There are several methods that you can use to measure the amount of water in the oil, such as spectrometry, spectroscopy, chromatography, and calcium hydride method. After that, you can use the transformer oil dehydration process, which is the best way to get rid of water and make oil cleaner.

2. Wide Use in Automotive Industry

As you already know, engines are using various types of oils for the proper function of their main parts. The key feature is the prevention of traction, which ensures parts with a longer lifespan and improved security. It is very important to maintain your vehicle properly, which also includes oil removal. This process is important because the oil can become full of particles over time, which can affect the features of the engine, and cause malfunction. Since different models are using petrol and diesel, you should know that you will need diverse types of oil for them, which requires distinctive methods of purifying as well.

3. Use in Productions is Essential

We already mentioned the wide use of hydraulic systems that are applied in various industries. Machines that are working under high pressure require proper lubrication and oils in their systems to have enough power and represent a safer environment for workers as well. In that matter, it is not a surprise that big manufacturers choose to buy a purifier to be sure that their machines are provided with proper liquid all the time.

Also, you can save a lot of money since you can purify the same oil over and over again. If you choose a lubricating purifier, you can ensure the oil with dehydration, degassing, and make it clean of particles. There are some most recent models that you can apply directly on the machines, where it can automatically clean the oil at required intervals.

4. You Can Constantly Purify the Same Oil

The main advantage of this system is that you can apply it to the machines and use it over and over again while cleaning the same liquid. We can apply this technique in many industries, and even on vehicles. Standard oil has a feature where it doesn’t waste over time. However, the main reason for replacement or cleaning is that it can collect other particles that might affect its effectiveness. Therefore, you should learn how to test it, and apply the proper method of cleaning. You can save a lot of money this way. That is especially beneficial for bigger machines, ships, and production lines.

There are different processes applied to oils, like filtration, centrifuge, vacuum, and sedimentation. Filtration can remove additional particles and dirt, a centrifuge is used to remove the water from it, the vacuum will remove gasses, while sedimentation the first step, where oil is being separated from the water and solid materials.

The Bottom Line

It is also common for the electrical industry to implement this method to assure the machines with higher performance. For example, electric transformers are using oil, which can collect various materials over time, and cause less efficiency. In that matter, it is essential to notice it on time and apply this process to reduce the chance of some serious malfunction. The oil in this device serves for cooling, insulating, and improved the security of the whole system.

Since there are different applications required for a variety of engines and machines, it is essential to contact professionals who can determine the right product and design. The size of the purifier can be especially important if you are planning to apply the process on machines that are not close to each other. Therefore, you can select a product that can be easily transported to various places.

It is a common misconception that industrial oil can serve you for a limited time and that you must replace it after. It can be the best option for vehicles and people who operate with only a couple of hydraulic machines. However, if you own bigger manufacture, this option is crucial since it will ensure higher performances, better efficiency, and cost-effectiveness. Also, you will need an expert who knows how to properly operate with the purifier.